Barton Digital is a full-service contract manufacturer, based in Cedar Rapids, Iowa, serving accounts nationwide. Products include most any type of electrical and electronic equipment. We design and manufacture wire harnesses, cable assemblies, PCB assemblies and embedded processors systems. We specialize in cable and harness assemblies for use in severe-environments, such as commercial vehicles, off-road machinery and heavy-industrial applications.

We offer complete design, prototype and development services, as well as turn-key manufacturing capabilities. We serve both the OEMs and end-users of electronic and electrical products and services. We also design and manufacture our own IntuiTime line of Commercial and Industrial timing systems.

We offer complete design, prototype and development services, as well as turn-key manufacturing capabilities. We serve both the OEMs and end-users of electronic and electrical products and services. We also design and manufacture our own IntuiTime line of Commercial and Industrial timing systems.

Some of our customers include: Boeing Aerospace, Rockwell Collins, Siemens Transportation, MCI, Northrop Grumman, Newport News Shipbuilding, Qwest Communications, AT&T, Ameritech, Cleveland Clinic, U.S.Cellular, Terex, St.Jude Medical, DeLaRue, Glory Global, United Parcel Service, Oral B Laboratories.

We have degreed Electrical Engineers on staff and we are Rockwell RC-9000 Certified.

We have degreed Electrical Engineers on staff and we are Rockwell RC-9000 Certified.

Contract Manufacturers abound •• what sets Barton Digital apart from the others?"

We are real! Barton Digital is a "brick and mortar" company, with over 30 years' experience. When you call, you will not be treated like a distraction. You will be treated like the important customer you are, regardless of your company's size or stature.

We are professionals! Barton Digital firmly believes that adherence to industry-standard documentation and business practices is just as important as the design and production of a quality product.

Engineering Documentation One of the key components of responsible product design is the product's engineering documentation, because it literally defines the product. These drawings define every aspect of the product, including the all-important Bill of Materials which lists each and every purchased component as well as any custom components.

Our Skills Highly-trained professional production staff. In addition to technical skills, all production personnel are required to understand engineering drawing system and configuration controls. All personnel are formally trained to interpret all aspects of engineering drawings.

Configuration Control All products, regardless of complexity, are completely documented in formal Engineering Drawing System which is kept under strict Rev. Level control. System allows for Configuration Control authority to be re-assigned to customer upon request. Major product or documentation changes, or changes requiring historical data, are documented by ECO and cross-referenced to drawing's Revision History.

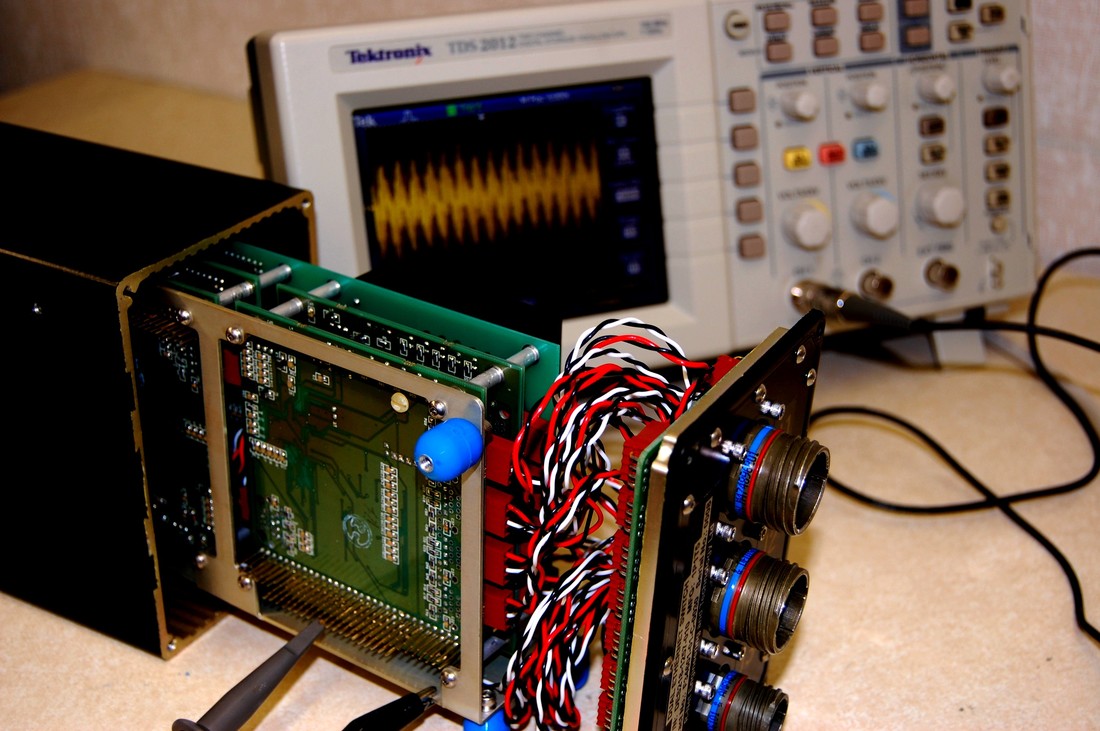

Testing Computerized production testing. Continuity tests are performed with automated tester which scans entire continuity matrix (up to 192 nodes per test pattern). Functional testing performed with custom-designed fixtures.

Inspection All products subject to 100% formal inspection, both mid-stream and final.

Traceability Serialization and tracking of non-expendable products. Product-return history tracking to detect and prevent DOA/NTF cycling.

We are real! Barton Digital is a "brick and mortar" company, with over 30 years' experience. When you call, you will not be treated like a distraction. You will be treated like the important customer you are, regardless of your company's size or stature.

We are professionals! Barton Digital firmly believes that adherence to industry-standard documentation and business practices is just as important as the design and production of a quality product.

Engineering Documentation One of the key components of responsible product design is the product's engineering documentation, because it literally defines the product. These drawings define every aspect of the product, including the all-important Bill of Materials which lists each and every purchased component as well as any custom components.

Our Skills Highly-trained professional production staff. In addition to technical skills, all production personnel are required to understand engineering drawing system and configuration controls. All personnel are formally trained to interpret all aspects of engineering drawings.

Configuration Control All products, regardless of complexity, are completely documented in formal Engineering Drawing System which is kept under strict Rev. Level control. System allows for Configuration Control authority to be re-assigned to customer upon request. Major product or documentation changes, or changes requiring historical data, are documented by ECO and cross-referenced to drawing's Revision History.

Testing Computerized production testing. Continuity tests are performed with automated tester which scans entire continuity matrix (up to 192 nodes per test pattern). Functional testing performed with custom-designed fixtures.

Inspection All products subject to 100% formal inspection, both mid-stream and final.

Traceability Serialization and tracking of non-expendable products. Product-return history tracking to detect and prevent DOA/NTF cycling.

Configuration Control All products, regardless of complexity, are completely documented in formal Engineering Drawing System which is kept under strict Rev. Level control. System allows for Configuration Control authority to be re-assigned to customer upon request. Major product or documentation changes, or changes requiring historical data, are documented by ECO and cross-referenced to drawing's Revision History.

Testing Computerized production testing. Continuity tests are performed with automated tester which scans entire continuity matrix (up to 192 nodes per test pattern). Functional testing performed with custom-designed fixtures.

Inspection All products subject to 100% formal inspection, both mid-stream and final.

Traceability Serialization and tracking of non-expendable products. Product-return history tracking to detect and prevent DOA/NTF cycling.

Testing Computerized production testing. Continuity tests are performed with automated tester which scans entire continuity matrix (up to 192 nodes per test pattern). Functional testing performed with custom-designed fixtures.

Inspection All products subject to 100% formal inspection, both mid-stream and final.

Traceability Serialization and tracking of non-expendable products. Product-return history tracking to detect and prevent DOA/NTF cycling.